Infrastructure

Feeder unit

Transport Unit

Infrastructure

Our Manufacturing Facility is equipped with high-speed production machine with the capacity to manufacture 110 mask per minute.

Feeder Unit

Our fully automatic feeder unit, has 4 rollers to feed 4 layers for the mask. Edge Sealing and Cutting Unit: In this unit, automatic insertion of nose bridge happens along with the folding of the fabric into the mask shape. Ultrasonic hot melt setting on both sides seals the mask and cut into the required dimension.

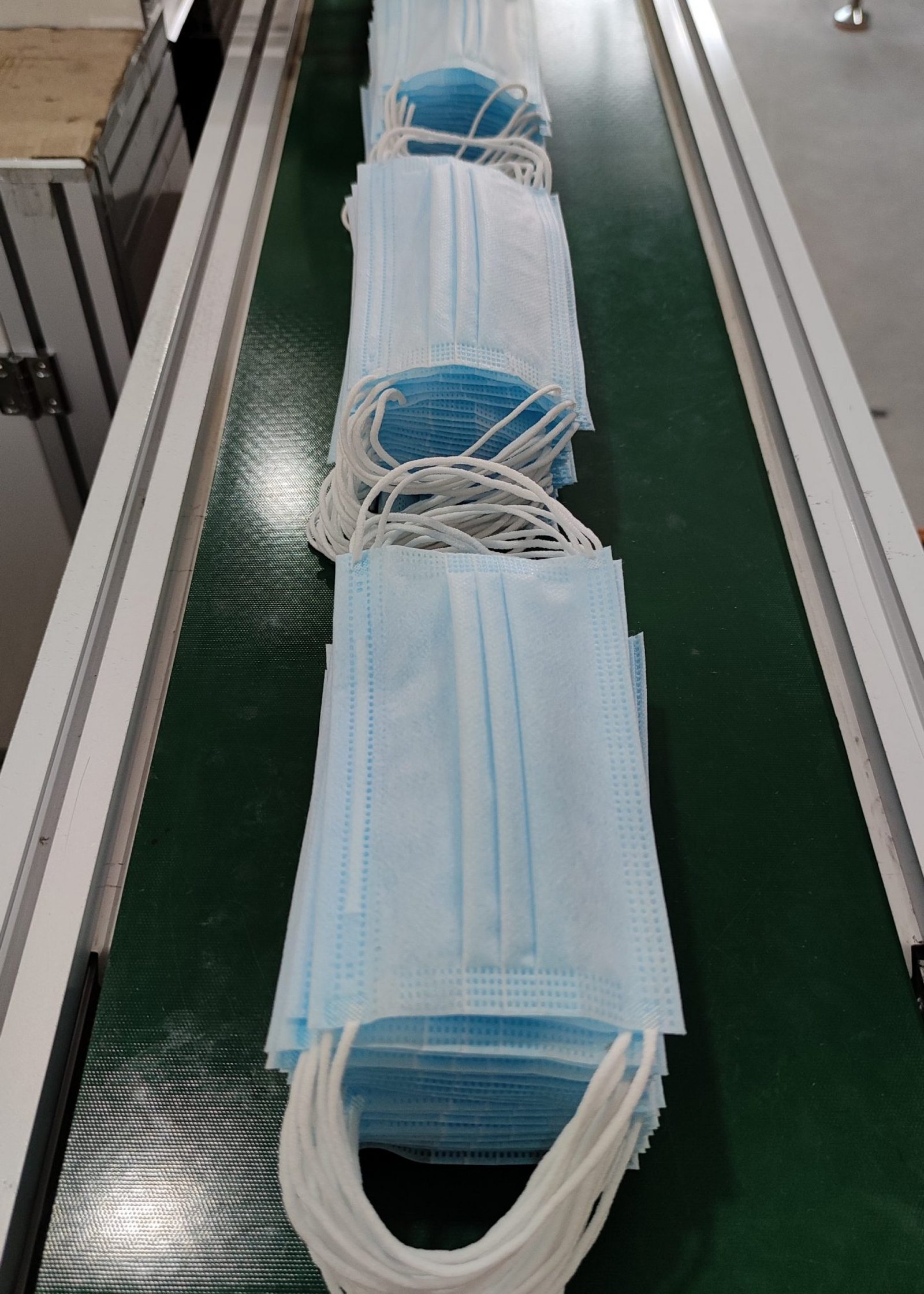

Transport Unit

Automatic over turn conveying to two groups of adhesive ear belt. This unit is aided with Photoelectric automatic detection unit for the presence of mask.

Welding Ear Loop

Automatic pneumatic manipulator traction positions and determines the ear loop length. Then, Ultrasonic welding of ear loop happens.

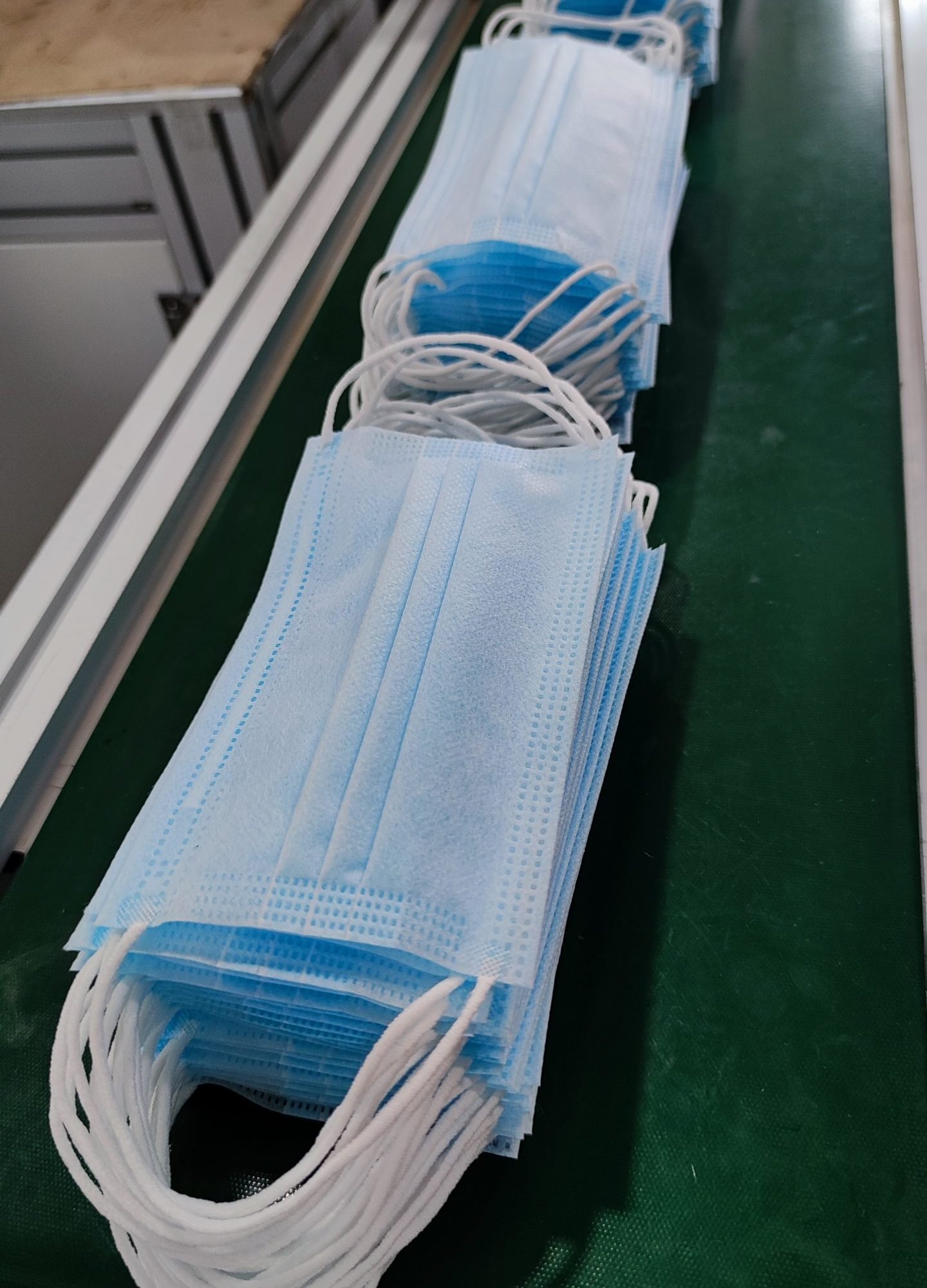

Stacker

Earloop turned inside to facilitate packing. Counts the mask and stacks them for packing.

Welding Ear Loop